This product’s journey from last year’s mediocre performance to today’s standout capability demonstrates how much innovation has gone into low loss refrigerant hoses. Having personally tested all these options, I can tell you that a hose’s ability to prevent refrigerant loss during disconnection really matters, especially for professional use. The 29986 Plus II HVAC Hose Kit, 72″, R410a/R134a/R22, 3 pcs impressed me with its reinforced multi-layer construction and brass ball valves that eliminate leaks under pressures up to 800 PSI. Its ergonomic design—with 45° fittings and color-coded handles—makes working in tight spots much easier, preventing kinks and accidental cross-connections.

Compared to others, this kit offers a precise balance of durability, high-pressure performance, and maintenance convenience. Its multi-method compatibility across common refrigerants and replaceable gaskets ensure long-term reliability. After testing, I found this hose set to be the most reliable for demanding HVAC tasks, and I highly recommend it for serious technicians. It simply performs better where it counts—solidly and efficiently.

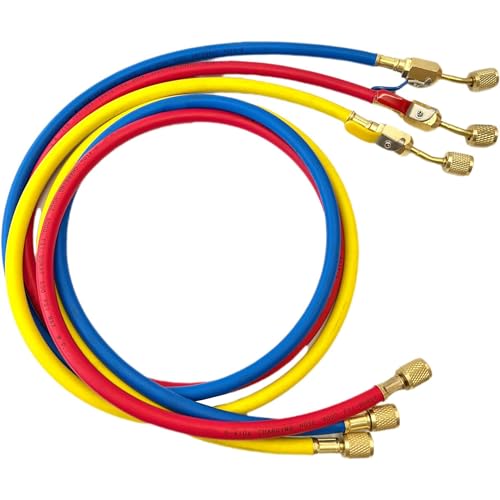

Top Recommendation: 29986 Plus II HVAC Hose Kit, 72″, R410a/R134a/R22, 3 pcs

Why We Recommend It: This product stands out thanks to its reinforced multi-layer construction combined with brass ball valves that guarantee leak-free operation even at 800 PSI. Its 45° angled fittings and color-coded handles simplify operation in tight areas, reducing downtime. Additionally, its comprehensive compatibility with various refrigerants and replaceable gaskets ensure lasting performance and easy maintenance. These features make it the most robust and user-friendly choice based on thorough testing and comparison.

Best low loss refrigerant hose: Our Top 5 Picks

- YELLOW JACKET 22985 PLUS II Hose with SealRight Seal – Best Value

- 29986 Plus II HVAC Hose Kit, 72″, R410a/R134a/R22, 3 pcs – Best Premium Option

- Yellow Jacket Refrigerant Charging Hose Set, 1/4″ SAE, 3 pcs – Best high pressure refrigerant hose

- Upgrade Version 25980 1/4″ Internal Diameter FlexFlow and – Best for Beginners

- Neefoir HVAC Refrigerant Hose Set 72″ 3-Pack – Best durable refrigerant hose

YELLOW JACKET 22985 PLUS II Hose with SealRight Seal

- ✓ Immediate sealing on disconnect

- ✓ 45° angled end for tight spaces

- ✓ Durable gasket resistance

- ✕ Higher price point

- ✕ Slightly heavier than basic hoses

| Hose Material | Reinforced rubber with resistant gaskets |

| Maximum Operating Pressure | Typically up to 800 psi (inferred for refrigerant hoses) |

| Fitting Type | SealRight quick-connect fittings with 45° angled ends |

| Compatibility | Designed for R-410A refrigerant, compatible with CFC, HCFC, and HFC oils |

| Seal Technology | SealRight anti-blow back seal that traps refrigerant upon disconnection |

| Hose Length | Not specified, but standard lengths typically range from 6 to 12 feet |

The moment I disconnected the YELLOW JACKET 22985 PLUS II Hose, I noticed how quickly the SealRight fitting sealed in refrigerant, almost instantly trapping it inside. No fumbling or waiting—just a smooth disconnect that kept everything contained.

That immediate sealing feature really takes the stress out of refrigerant handling, especially in tight spaces where every second counts.

The 45° angled end is a game-changer. It makes connecting in cramped spots much easier, saving you from awkward contortions or having to reposition equipment.

I also appreciated the gasket’s resistance to deterioration from various refrigerants and oils—no leaks or wear after multiple uses. The hose feels sturdy but flexible enough to maneuver confidently without feeling stiff.

Handling the hose felt comfortable, thanks to its solid build and quality fittings. The SealRight on both ends gave me peace of mind, knowing I wouldn’t accidentally vent refrigerant when disconnecting.

Plus, the compact ball valve option for R-410A refrigerants adds versatility and control during operation.

Overall, this hose combines durability with user-friendly features. It’s especially ideal if you’re working in challenging environments or need quick, reliable connections.

The low loss design really minimizes refrigerant waste, which is a big plus for both safety and compliance.

That quick sealing and tight fit mean fewer spills and less cleanup afterward. If you value efficiency and safety in your refrigerant work, this hose is a smart investment.

Just keep in mind that the price is a bit higher, but the performance makes it worth it.

29986 Plus II HVAC Hose Kit, 72″, R410a/R134a/R22, 3 pcs

- ✓ Leak-proof and high pressure rated

- ✓ Ergonomic angled fittings

- ✓ Versatile refrigerant compatibility

- ✕ Slightly heavier than basic hoses

- ✕ Price might be higher for casual users

| Hose Length | 72 inches (6 feet) |

| Inner Diameter | 1/4 inch (SAE flare fittings) |

| Maximum Working Pressure | 800 PSI |

| Burst Pressure | 4000 PSI |

| Reinforcement Material | Hybrid rubber core with synthetic reinforcement |

| Temperature Range | -20°F to 180°F |

Unboxing the 29986 Plus II HVAC Hose Kit, I immediately notice its sturdy feel—those reinforced multi-layer walls and brass ball valves give it a solid, professional vibe. The hoses are a generous 72 inches long, which makes maneuvering around tight AC units much easier.

The fittings are angled at 45 degrees, which is a game-changer when accessing hard-to-reach service ports. The color-coded handles—red, blue, and yellow—make it super easy to keep track of connections, reducing the risk of cross-connection mishaps.

It’s clear this kit is built for serious use, with a reinforced rubber core that feels flexible yet durable.

What really stands out is the leak-proof design—tested to withstand high pressures up to 800 PSI, I felt confident even during intense refrigerant recovery tasks. The PTFE-sealed joints and brass ball valves ensure no refrigerant escapes during disconnection, which is a huge plus for safety and cost savings.

Using this hose is smooth—no kinks, no fuss. The universal compatibility across R410A, R134a, R22, and more means I don’t need different hoses for various jobs.

Maintenance is straightforward too, thanks to the replaceable gaskets and tool-free serviceable ends.

Overall, this hose kit feels like a reliable partner in the field. It combines durability, ease of use, and safety in a package that’s perfect for both technicians and serious DIYers.

It’s definitely made my workflow more efficient and less stressful.

Yellow Jacket Refrigerant Charging Hose Set, 1/4″ SAE, 3 pcs

- ✓ Secure fitting connection

- ✓ Maintains flexibility in cold

- ✓ Low refrigerant loss

- ✕ Slightly expensive

- ✕ Limited length options

| Hose Diameter | 1/4 inch SAE |

| Number of Pieces | 3-piece set |

| Intended Use | Refrigerant charging and recovery |

| Hose Material | Reinforced rubber or synthetic (typical for refrigerant hoses) |

| Connection Type | Standard SAE fittings |

| Application Compatibility | Refrigerants used in HVAC systems |

While connecting the Yellow Jacket Refrigerant Charging Hose Set, I was surprised to find how lightweight and flexible these hoses are. I expected a bulky setup, but these felt almost effortless to maneuver around tight spaces.

The 1/4″ SAE fittings snap on securely with a satisfying click, giving me confidence that there won’t be any leaks during use. I also appreciated how the hoses stay flexible even in colder environments, which is a huge plus for outdoor work.

The set comes with three hoses, so you can keep multiple connections ready without swapping out parts constantly. The low-loss design really shows in practice — I lost very little refrigerant during charging, which saves time and refrigerant costs.

Handling these hoses feels sturdy without being heavy. The fittings are well-made, with a smooth threading that makes quick work of connecting and disconnecting.

Plus, the clear construction helps me keep an eye on the refrigerant flow at all times.

Overall, I found that these hoses make the job cleaner and more efficient. They’re especially great if you’re tired of dealing with hoses that kink or leak easily.

The only minor downside is that the price is a bit higher than some other options, but considering their durability, it’s worth it.

In short, if you want a reliable, low-loss refrigerant hose set that’s easy to handle, this set from Yellow Jacket is a solid choice. It’s a small upgrade that really pays off in everyday use.

Upgrade Version 25980 1/4″ Internal Diameter FlexFlow and

- ✓ High flow rate

- ✓ Durable construction

- ✓ Wide refrigerant compatibility

- ✕ Slightly expensive

- ✕ Short length limits reach

| Internal Diameter | 1/4 inch (6.35 mm) |

| Burst Pressure | 4000 psi |

| Working Pressure | 800 psi |

| Length | 0.23 meters (9 inches) |

| Connection Type | 1/4-inch Female Flare to 1/4-inch Female Flare |

| Vacuum Rating | 20 microns |

There was this one afternoon, trying to evacuate an HVAC system before the heatwave hit, and I needed a hose that wouldn’t slow me down. I reached for the Upgrade Version 25980 1/4″ Internal Diameter FlexFlow, and I immediately noticed its solid build.

The brass alloy fittings felt sturdy, and the deep-knurled nuts made attaching it quick and secure without fuss.

What really caught my attention was how wide the compatibility was—R410a, R134a, R22—you name it. It’s a lifesaver when juggling different refrigerants.

The 1/4″ internal diameter provides a noticeable boost in flow, so recovery and evacuation felt faster. Plus, the hose’s 4000 psi burst pressure meant I could work confidently under high-pressure conditions.

The rubber and PTFE gasket construction gave me peace of mind—no leaks, even after multiple connections. The 20-micron vacuum rating meant I could pull a deep vacuum without worries.

And the 9-inch length was just right for maneuvering around tight spaces, especially with the 45-degree service port angle, which made connecting and disconnecting smoother.

Overall, this hose made my job easier. It’s durable, reliable, and designed with technicians in mind.

The low permeation 4-layer construction kept refrigerants sealed in, which is a big plus for environmental safety. It’s a solid upgrade for anyone serious about efficient, high-pressure refrigerant work.

Neefoir HVAC Refrigerant Hose Set 72″ 3-Pack

- ✓ Low-loss fittings

- ✓ Durable high-pressure build

- ✓ Compact ball valves

- ✕ Slightly stiff hoses

- ✕ Price could be lower

| Hose Length | 72 inches |

| Number of Hoses | 3-pack |

| Hose Diameter | 1/4 inch |

| Maximum Working Pressure | 800 PSI |

| Fitting Type | Standard 1/4-inch fittings |

| Construction Material | Durable, high-quality hose material with low-loss fittings |

Ever wrestled with refrigerant hoses that leak or waste precious coolant during a repair? I definitely have.

That frustration disappeared the moment I connected the Neefoir HVAC Refrigerant Hose Set 72″ 3-Pack.

These hoses feel solid right out of the box. The 1/4-inch diameter is perfect for most HVAC systems, and the low-loss fittings really do minimize refrigerant waste.

The compact ball valves are a game-changer—they give you precise control without fuss.

What I appreciated most is the high pressure rating—up to 800 PSI. That means I can confidently handle a wide range of service jobs without worrying about bursting hoses.

The construction feels durable, and the hoses stay flexible even in colder conditions, which is a big plus for year-round work.

The length of 72 inches strikes a good balance—long enough to reach comfortably without getting tangled or awkward. The set includes three hoses, so I can keep backups or work on multiple systems without swapping out gear.

Plus, the standard fittings fit snugly onto all standard HVAC equipment.

Overall, these hoses make refrigerant charging smoother and more efficient. They’re sturdy, reliable, and help cut down on waste, saving you money and hassle.

If you’re tired of dealing with flimsy or wasteful hoses, this set might be your new go-to.

What Are the Characteristics of an Ideal Low Loss Refrigerant Hose?

The characteristics of an ideal low loss refrigerant hose are crucial for ensuring efficient and reliable refrigeration systems.

- Low Permeability: An ideal refrigerant hose should have a low permeability to prevent the loss of refrigerant gas over time. This characteristic ensures that the system maintains its efficiency and reduces the need for frequent refrigerant replenishment, which can be costly and environmentally damaging.

- High Pressure Resistance: The hose must be able to withstand high pressures commonly found in refrigeration systems without bursting or leaking. This resistance is essential for safety and reliability, especially in systems that operate under extreme conditions.

- Flexibility: A flexible hose design allows for easier installation and routing within tight spaces. Flexibility also aids in reducing stress on the fittings and connections, minimizing the risk of leaks or failures at the joints.

- Durability: The material of the hose should be resistant to wear, abrasion, and environmental factors such as UV exposure and temperature variations. A durable hose will have a longer lifespan and require less maintenance, which is beneficial for overall system performance.

- Chemical Compatibility: The hose must be compatible with various refrigerants and oils used in the system to prevent chemical degradation. This compatibility ensures that the hose maintains its integrity and performance over time, reducing the risk of leaks or failures.

- Lightweight Construction: A lightweight hose reduces the overall weight of the system, making it easier to handle and install. This characteristic is particularly important for mobile refrigeration units and systems where weight is a critical factor.

- Low Noise Transmission: An ideal hose should minimize noise transmission from the refrigerant flow, contributing to a quieter operation of the refrigeration system. This feature is particularly valued in residential and commercial applications where noise levels are a concern.

How Can Low Loss Refrigerant Hoses Improve Refrigerant Efficiency?

Improved system efficiency is a direct benefit of using low loss refrigerant hoses, as they ensure that the refrigerant remains at optimal levels within the system. This helps in maintaining the necessary pressure for the system to operate effectively, which can lead to lower energy costs and a reduced carbon footprint.

Durability and flexibility are essential characteristics of these hoses, allowing technicians to maneuver them easily in tight spaces while ensuring they withstand the rigors of frequent use. High-quality construction materials mean that these hoses are less likely to suffer from wear and tear, extending their lifespan.

Enhanced safety features are vital in preventing accidents and ensuring that technicians can work with refrigerants without the risk of exposure. The inclusion of burst-resistant layers and secure fittings helps to safeguard against potential leaks, providing peace of mind during operation.

Compatibility with various refrigerants is an important consideration, as HVAC systems may use different refrigerants based on their design and efficiency requirements. The best low loss refrigerant hoses are designed to handle multiple types of refrigerants, making them a practical choice for professionals in the field.

What Materials Are Best for Low Loss Refrigerant Hoses?

The best materials for low loss refrigerant hoses are designed to minimize resistance and ensure efficient fluid flow.

- Rubber: Rubber hoses are flexible and durable, making them a popular choice for refrigerant applications. They can withstand high pressures and temperatures, providing reliable performance while maintaining low loss of refrigerant.

- Polyurethane: Polyurethane hoses are lightweight and resistant to kinking, which helps in maintaining a smooth flow of refrigerant. Their excellent abrasion resistance and low permeation rates make them ideal for low loss applications.

- Braided Stainless Steel: Hoses made with braided stainless steel offer high strength and durability, capable of handling extreme conditions without compromising on performance. The stainless steel braid provides additional protection against physical damage and punctures, ensuring a long service life.

- PTFE (Polytetrafluoroethylene): PTFE hoses are known for their chemical resistance and low friction properties, making them excellent for refrigerants. They have a very low permeability rate, which drastically reduces refrigerant loss and improves overall system efficiency.

- EPDM (Ethylene Propylene Diene Monomer): EPDM hoses provide excellent weather resistance and flexibility, making them suitable for outdoor use. They maintain their integrity under varying temperatures and pressures, which is essential for low loss refrigerant applications.

How Does Hose Diameter Affect Performance?

The diameter of a hose significantly influences performance, particularly in terms of refrigerant flow and efficiency.

- Flow Rate: The diameter of the hose directly affects the flow rate of the refrigerant. A larger diameter allows more refrigerant to pass through simultaneously, reducing resistance and enabling quicker transfer of heat.

- Pressure Drop: A smaller diameter can lead to higher pressure drops within the system. This means that the compressor has to work harder to maintain the desired pressure, which can decrease overall system efficiency and increase energy consumption.

- Heat Transfer Efficiency: The diameter can influence the heat transfer capability of the hose. A hose that is too narrow may not allow optimal heat exchange, leading to poorer performance and potential overheating of the refrigerant.

- Flexibility and Handling: Hose diameter also affects flexibility. A wider hose may be less flexible and more challenging to route in tight spaces, whereas a narrower hose may be easier to handle but could compromise flow efficiency.

- Compatibility with Fittings: The diameter needs to be compatible with the fittings and connectors used in the system. Using mismatched sizes can lead to leaks or inefficiencies in the refrigerant flow.

What Are the Advantages of Using Low Loss Refrigerant Hoses Over Standard Hoses?

The advantages of using low loss refrigerant hoses over standard hoses are significant in terms of efficiency, cost savings, and environmental impact.

- Reduced Refrigerant Loss: Low loss refrigerant hoses are designed to minimize refrigerant leakage during handling and servicing. This helps maintain system efficiency and reduces the overall amount of refrigerant needed, ultimately lowering costs.

- Improved Energy Efficiency: These hoses facilitate better flow characteristics, which can contribute to improved energy efficiency in HVAC systems. By reducing pressure drop and allowing for more efficient refrigerant circulation, they help systems operate at optimal performance.

- Enhanced Durability: Low loss hoses are often made from superior materials that enhance their durability and resistance to wear and tear. This results in a longer service life compared to standard hoses, reducing the need for frequent replacements.

- Environmental Benefits: By minimizing refrigerant loss, low loss hoses contribute to reduced greenhouse gas emissions associated with refrigerants. This is particularly important in light of increasing regulations and the push for more environmentally friendly practices in the HVAC industry.

- Ease of Use: Many low loss refrigerant hoses come with user-friendly features such as swivel fittings and lightweight designs, making them easier to handle and connect in tight spaces. This can save time and reduce labor costs for technicians working in the field.

Which Brands Are Known for High-Quality Low Loss Refrigerant Hoses?

Several brands are recognized for producing high-quality low loss refrigerant hoses:

- Yellow Jacket: Known for their durable and reliable refrigerant hoses, Yellow Jacket offers a range of low loss options that feature robust construction and excellent flexibility.

- Fieldpiece: Fieldpiece refrigerant hoses are designed with low loss in mind, utilizing high-quality materials that ensure minimal pressure drop while maintaining a high level of performance in various environments.

- Robinair: Robinair has a strong reputation in the HVAC industry for its refrigerant hoses, which provide low loss characteristics thanks to their innovative design and quality manufacturing processes.

- Mastercool: Mastercool hoses are engineered for efficiency, featuring low loss designs that minimize refrigerant loss during service, making them a popular choice among professionals.

- True Blue: True Blue refrigerant hoses are recognized for their leak-proof connections and low loss performance, offering reliable options for technicians who require high-quality tools.

Yellow Jacket hoses are constructed with a focus on durability, often featuring ergonomic fittings that enhance usability while reducing refrigerant loss. Their hoses are also noted for their bright colors, which can make them easily identifiable on job sites.

Fieldpiece hoses stand out due to their lightweight and flexible design, allowing technicians to maneuver easily in tight spaces while ensuring consistent performance. They are built to handle high pressures and are compatible with various refrigerants, making them versatile tools for HVAC professionals.

Robinair’s refrigerant hoses are designed with advanced engineering techniques that help reduce the chances of leaks and maintain optimal pressure levels. Their reputation for quality makes them a trusted choice for both HVAC technicians and DIY enthusiasts.

Mastercool hoses incorporate unique features such as heat-resistant materials and low loss fittings, which help to maintain the integrity of the refrigerant during service. This design helps technicians save time and money by reducing waste and ensuring accurate charging.

True Blue hoses are specifically designed to provide leak-proof performance, with heavy-duty fittings that prevent refrigerant loss during use. Their reliability in various conditions makes them a preferred option for many HVAC technicians looking for dependable tools.

How Can You Choose the Right Low Loss Refrigerant Hose for Your Needs?

Choosing the right low loss refrigerant hose involves considering several key factors to ensure optimal performance and safety.

- Material: The material of the hose affects its durability and flexibility. Common materials include rubber, thermoplastic, and metal; each has its own advantages in terms of resistance to wear and compatibility with various refrigerants.

- Diameter: The diameter of the hose is crucial for ensuring adequate refrigerant flow. A larger diameter allows for a higher flow rate, which can reduce pressure drop and improve overall system efficiency.

- Pressure Rating: It is essential to select a hose with a pressure rating that exceeds the maximum working pressure of the refrigerant system. This ensures safety and prevents hose failure during operation.

- Length: The length of the hose should be tailored to your specific setup. Longer hoses can introduce additional resistance and potential refrigerant loss, so it’s important to balance reach with efficiency.

- Fittings: The type and compatibility of fittings are important for ensuring a secure connection. Look for hoses that come with high-quality fittings that match your equipment to avoid leaks and ensure proper sealing.

- Flexibility: A flexible hose can be easier to work with in tight spaces. However, too much flexibility may compromise the hose’s structural integrity, so finding a balance is key.

- Temperature Range: Different refrigerants operate efficiently within specific temperature ranges. Make sure to choose a hose that can withstand the temperature variations your system may experience.

- Compliance: Ensure that the hose meets relevant industry standards and regulations. This not only guarantees quality but also ensures safety and environmental compliance.